CV joint | Rough、finish milling arc groove chamfering processing case

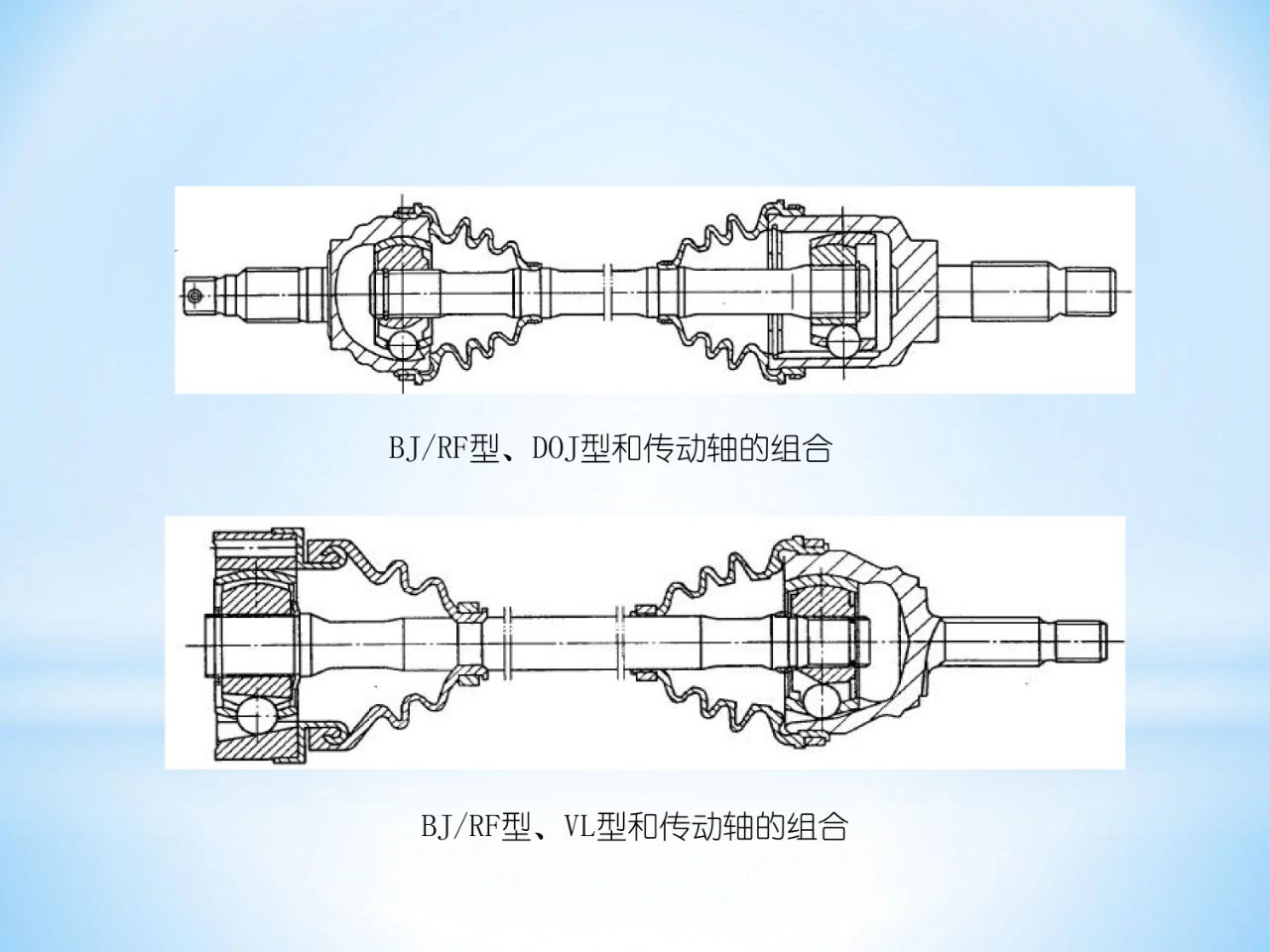

The constant speed universal joint drive shaft assembly can be divided into front wheel drive and rear wheel drive universal joint assembly according to the working performance;

Crafting process

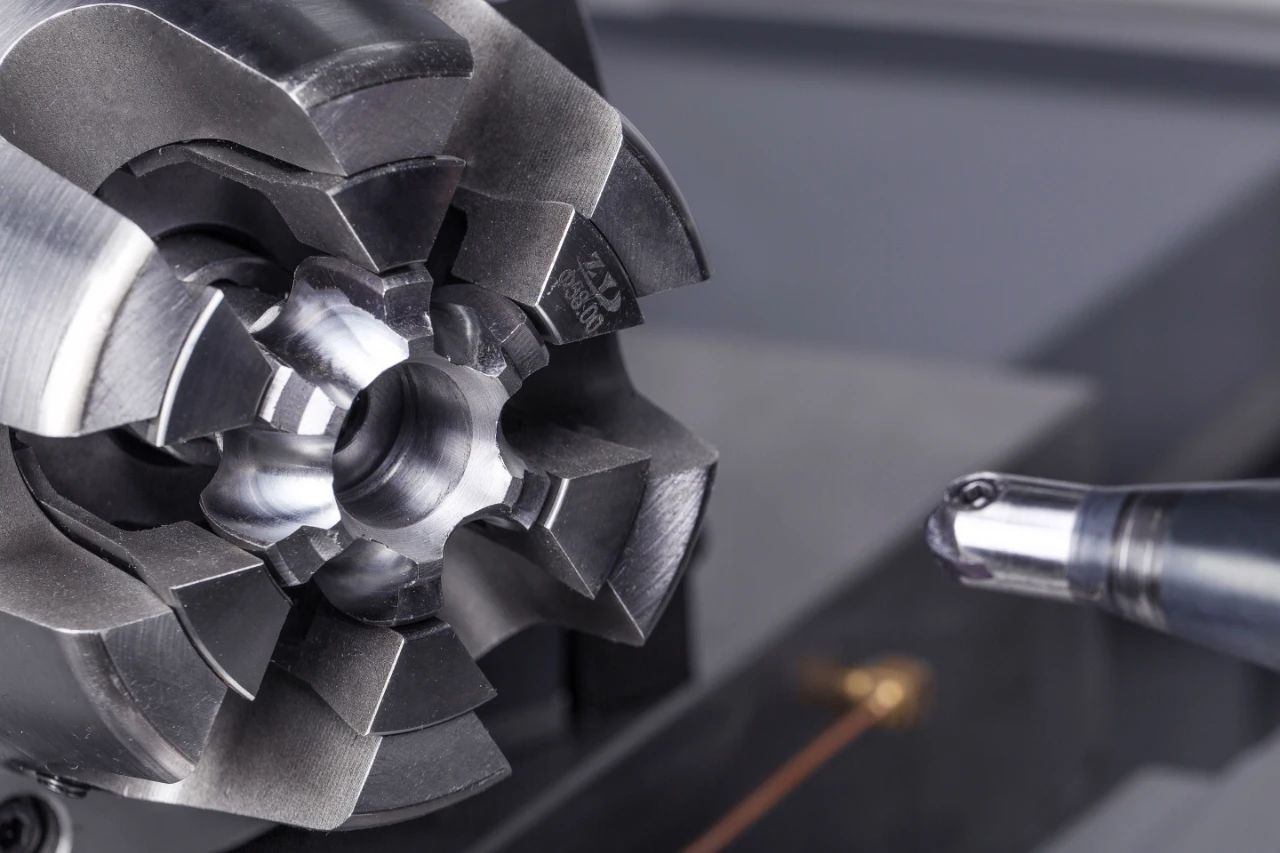

Workpiece case

| Workpiece name | BJ type outer race |

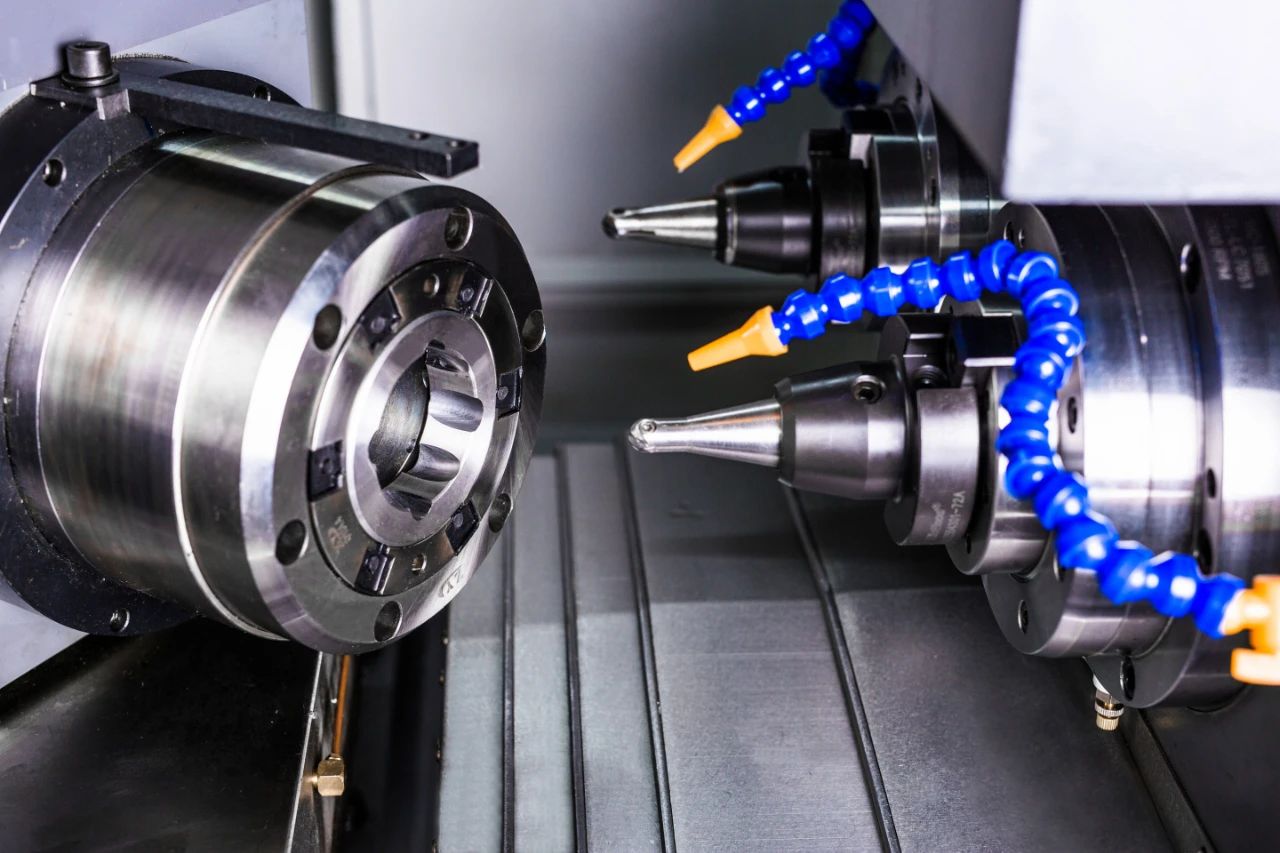

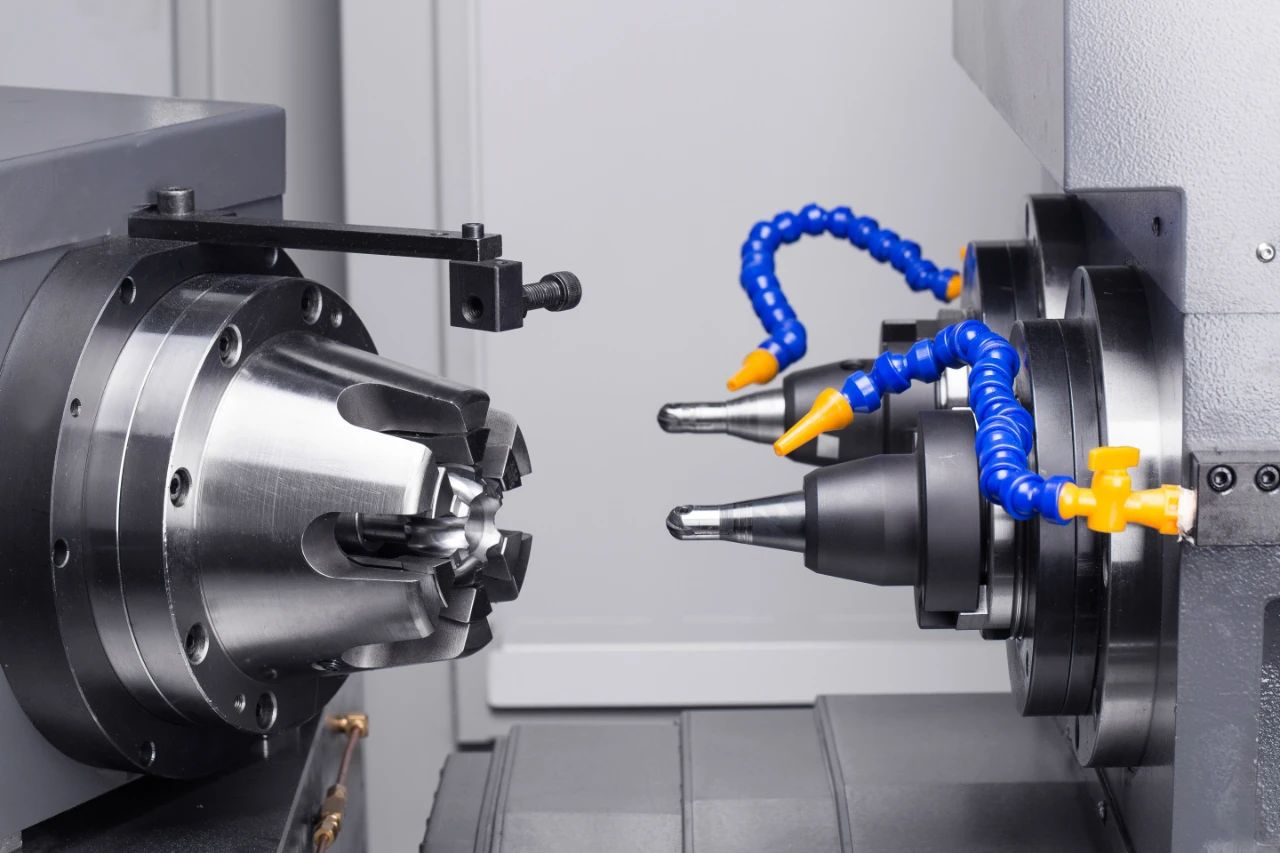

| Machine type | QXA125D |

| Manufacturing procedure | Groove milling+chamfering |

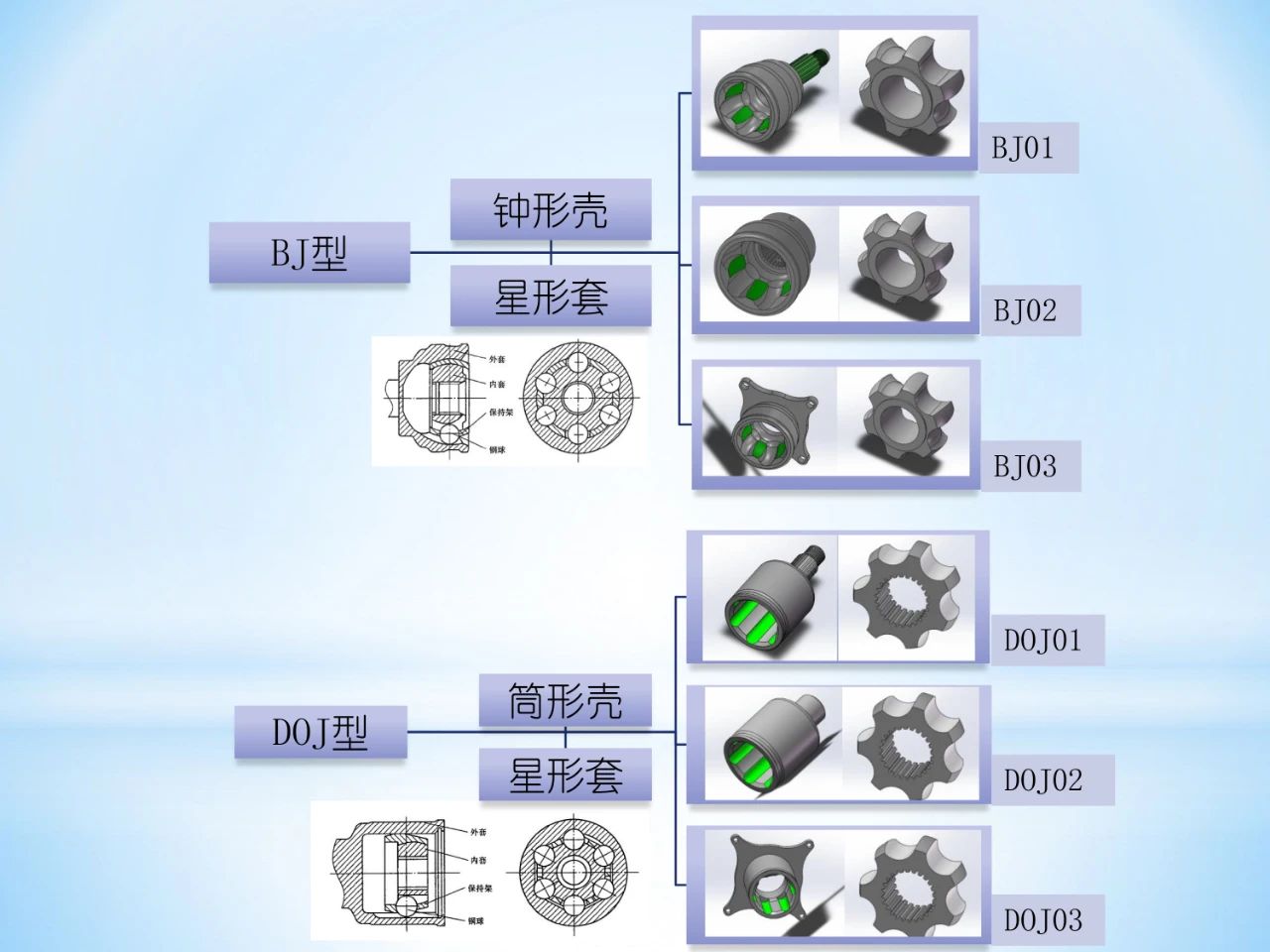

Structure diagram of CV joint:

The constant speed universal joint drive shaft assembly can be divided into front wheel drive and rear wheel drive universal joint assembly according to the working performance; It can be divided into the following types:

Performance feature:

◎ The milling of the arc groove of the outer race (or inner race) can be completed in turn with one clamping.

◎ Solid casting body, high rigidity rectangular hardened guide rail, durable;

◎ End gear type oil pressure indexing, high accuracy;

◎ Special hydraulic elastic fixture, reliable clamping, stable precision;

◎ High rigidity spindle with special structure, good seismic resistance and long service life;

◎ It can be equipped with truss or joint robot to support automatic wire connection.

◎ CV joint arc groove hard milling machine

◎ Hot after hard milling, milling instead of grinding, can simplify the process, strengthen the surface quality of the processed parts.

◎ Worm wheel low center of gravity turntable.

◎ Double position CV joint arc groove milling machine

◎ Double station structure, interpolation processing, rough, precision milling processing, high precision.