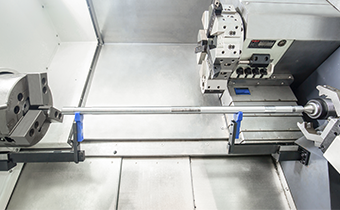

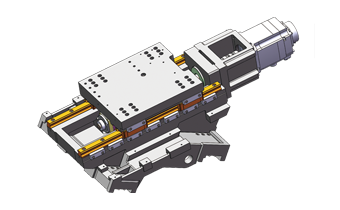

The full function lathe with our many years design experience, is more suitable for production line. High precision, front and back hand options, it can carry with truss or joint robot and automatical line.

Advantage

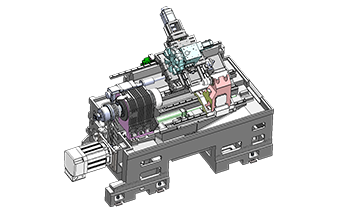

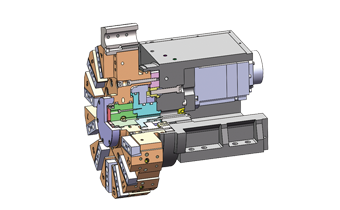

Stepped integral fuselage

High and low flat , long span guide rail, 30 degrees sliding saddle, strong rigidity, tight structure, easy chip removal.

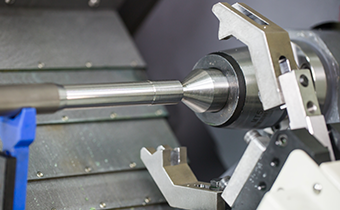

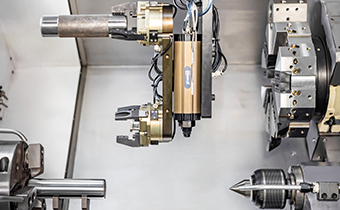

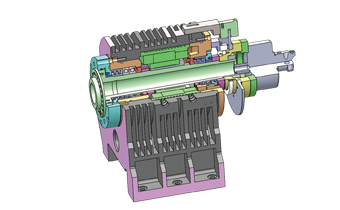

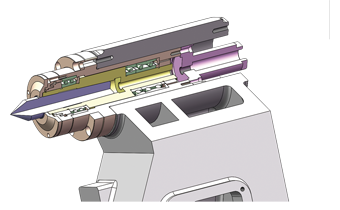

Built-in electric spindle (optional)

Built-in high-speed motor direct-drive, P4 bearing, hydraulic brake, compact structure, high speed,precisionand rigidity.

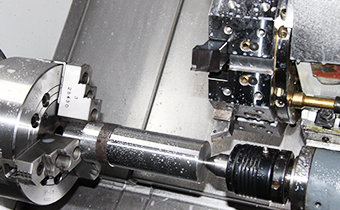

High pressure servo turret (optional)

Three-piece gear plate, servo drive, hydraulic lock, high precision and speed, water pressure up to 70kg.

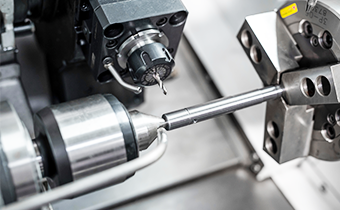

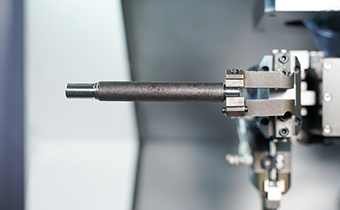

Spindle type tailstock (optional)

P4 bearing, MT4 top, labyrinth mechanical seal, long life, high processing cylindricity.

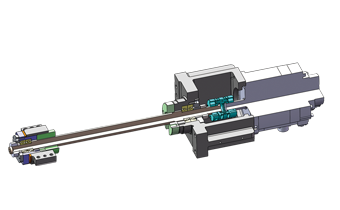

Pre-stretching of screw rod

C3 double-nut Screw, precision screw special bearings, transmission stability, thermal expansion after the accuracy of good retention.

Rapid displacement

P-class ball track, precision screw drive, fast moving 24m/min.

Technical Parameters

A CNC Lathe is a computer-controlled machine tool used primarily for precision turning operations, where material is rotated and a cutting tool is applied to remove material, shaping it into the desired form. These machines are essential in manufacturing for producing intricate and precise components from various materials such as metals, plastics, and wood.

High Precision: CNC lathes offer exceptional accuracy, making them ideal for producing parts with tight tolerances.

Automation: The CNC system automates the machining process, reducing manual intervention and increasing productivity.

Versatility: They can perform multiple operations such as facing, threading, drilling, and knurling in a single setup.

Efficiency: CNC lathes can operate continuously, maximizing production efficiency.

Consistency: Computer control ensures that every part produced is identical, maintaining high quality throughout production runs.

CNC lathes are integral to modern manufacturing, providing a blend of precision, efficiency, and versatility that meets the demands of today's industries. Welcome your consultation!

| ITEM | NL501 |

| Max Body Rotate Diameter, mm | Ø500 |

| Max Turning Diameter, mm | Ø360 |

| Max Turning Length, mm | 300 |

| Max Bar Diameter, mm | Ø50 |

| X/Z Aris, mm | 195/330 |

| Speed of Spindle, rpm | 3500 |

| Chuck Diameter, inch | 8 |

| Fore of Spindle | A2-6 |

| Tool Stations, pcs | 8 |

| TailstockTravel, mm | 300 |

Application Artifact