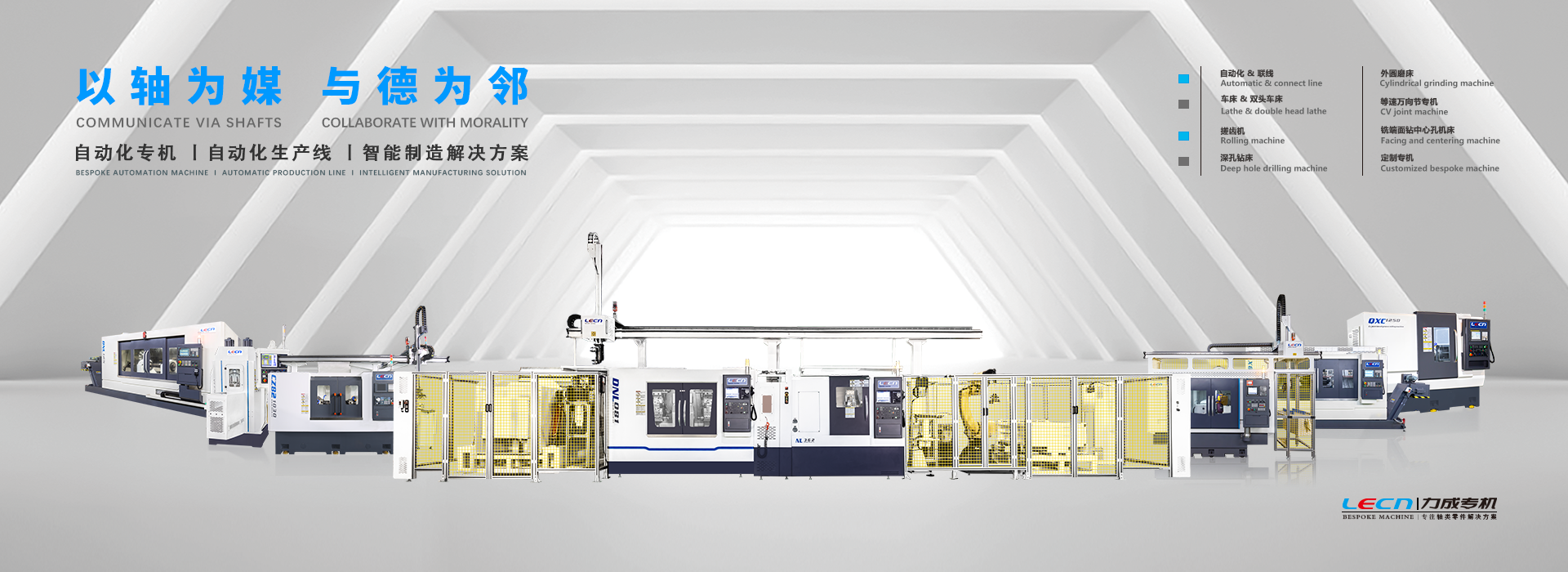

Customized Bespoke Machine

Versatility:

Combining boring and milling functions, it can complete multiple processing tasks on one workbench and improve production efficiency. It is suitable for various processing needs such as planes, curved surfaces, holes, slots, etc.

High precision:

Equipped with high-precision spindle and feed system, it can achieve micron-level processing accuracy. It adopts advanced CNC system to ensure the stability and repeatability of the processing process.

High efficiency:

Equipped with automatic tool change system (ATC), it can quickly change tools and reduce non-processing time. High spindle speed and fast feed speed improve processing efficiency.

Strong adaptability:

Suitable for processing large and heavy workpieces, such as parts in aerospace, shipbuilding, and energy equipment. It can handle workpieces with complex shapes and special structures.

High degree of automation:

Adopting advanced CNC system (CNC), it can realize automatic processing and reduce manual intervention.With self-diagnosis function, it can monitor and adjust processing parameters in real time to improve processing quality and efficiency.

Read More

Break Cam Milling Machine CM0525

Max Clamping Diameter: Ø50 mm

Max Cam Diameter: Ø250 mm

Joint Cross Machine CZ821030/TZ820510

Clamping Diameter Scope: Ø15-Ø60 mm

Boring Diameter Scope: Ø25-Ø50 mm

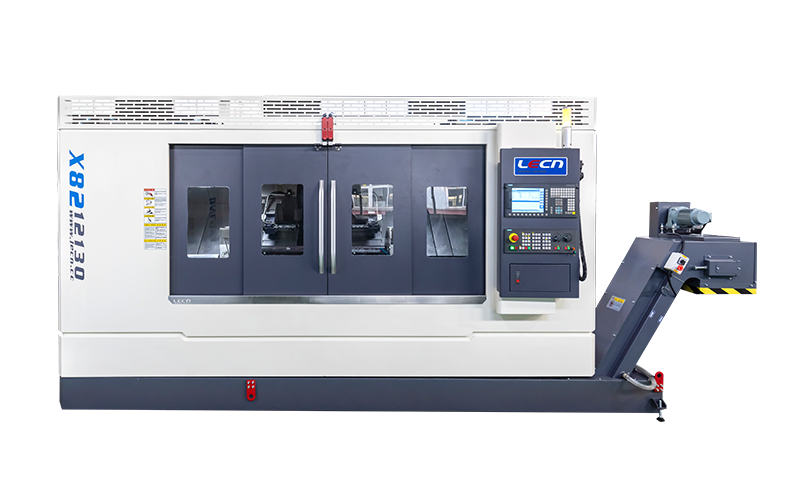

Automobile Torsion Beam Milling Machine X8220125

Workpiece Length Scope:1250-1550 mm

Oil Preforation Blind Hole Milling Bespoke Machine

Clamping Diameter Scope: Ø70 -Ø120 mm

Workpiece Length Scope: 400-1300 mm

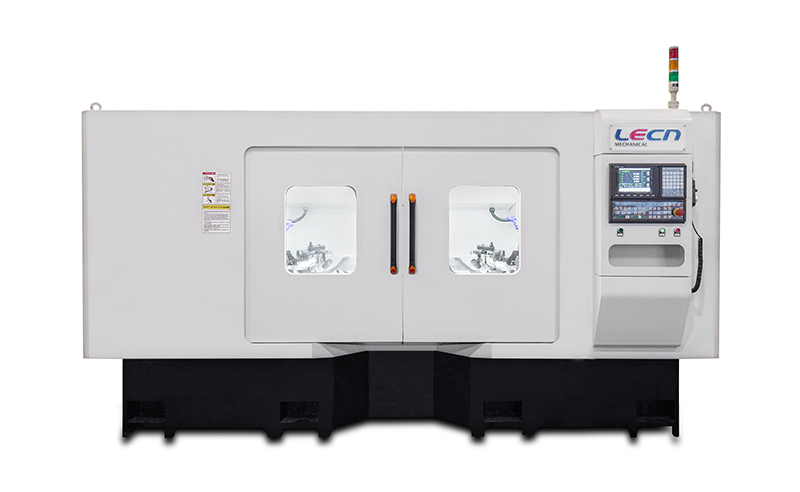

CNC Iinternal Grinding Machine

Max Clamping Diameter: Ø115 mm

Max Grinding Hole Diameter: Ø120 mm

Technology and Application