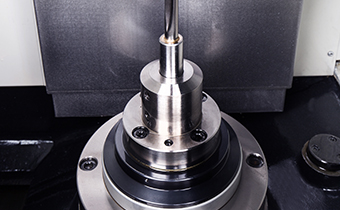

Deep hole drilling machine is a kind of special machine tool for deep hole processing with high precision, high efficiency and high automation. Depending on advanced hole processing technology (gun drill), the processing accuracy and surface roughness can be achieved by one continuous drilling process, which generally requires drilling, expanding and reaming processes. Machining hole size accuracy: IT7-IT11; Machining hole deviation: <0.5-1/1000 (Machining hole depth); Machining hole surface finish: Ra0.2-6.3um. It can carry with truss or joint robot and automatical line.

Advantage

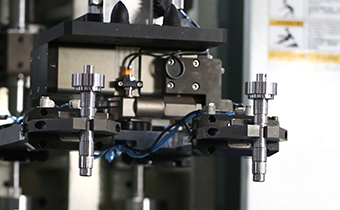

Special hydraulic modular fixture

Special structure, clamping reliable, accuracy stability.

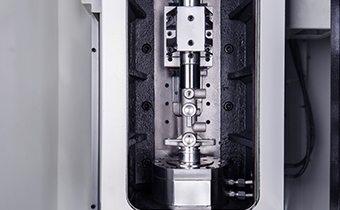

Special high rigidity spindle structure

Seismic resistance, long life.

Double cabin independent operation

2 or 4 stations option, high efficiency

Automation

Conversational interface,factory high stability automation.

Technical Parameters

A deep hole drilling machine is a metal cutting machine designed to machine very deep precision holes in almost any metal. Deep hole drilling machines can achieve the performance of specific tools such as BTA and gun drills, thereby optimizing the deep hole drilling process for manufacturers.

Deep Hole Drilling Equipment is very suitable for deep holes of various sizes and production levels, and is essential for holes with a depth-to-diameter ratio of approximately 20:1 or greater. Dedicated deep hole drilling machines provide tool support, coolant delivery and process feedback, enabling manufacturers to achieve their deep hole drilling goals. Compared with CNC machining centers, these functions optimize the process and give priority to deep hole drilling methods by shortening cycle time, stabilizing tools, discharging chips, and preventing tool breakage and process failures.

| ITEM | VSMGD0145D | VSMGD0145F |

| Max Drilling Diameter, mm | Ø5-Ø12 | Ø5-Ø12 |

| Max Clamping Diameter, mm | Ø60 | Ø60 |

| Max Workpiece Length, mm | 450 | 450 |

| Number Stations | 2 | 4 |

Application Artifact