Deep hole drilling machine is a kind of special machine tool for deep hole processing with high precision, high efficiency and high automation. Depending on advanced hole processing technology (gun drill), the processing accuracy and surface roughness can be achieved by one continuous drilling process, which generally requires drilling, expanding and reaming processes. Machining hole size accuracy: IT7-IT11; Machining hole deviation: <0.5-1/1000 (Machining hole depth); Machining hole surface finish: Ra0.2-6.3um. It can carry with truss or joint robot and automatical line.

Advantage

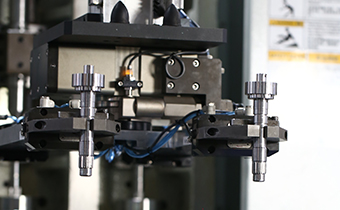

Special hydraulic modular fixture

Special structure, clamping reliable, accuracy stability.

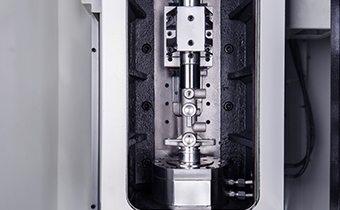

Special high rigidity spindle structure

Seismic resistance, long life.

Double cabin independent operation

2 or 4 stations option, high efficiency

Automation

Conversational interface,factory high stability automation.

Technical Parameters

| ITEM | VSMGD0245D | VSMGD0245F |

| Max Drilling Diameter mm | Ø10-Ø20 | Ø10-Ø20 |

| Max Clamping Diameter mm | Ø60 | Ø60 |

| Max Workpiece Length mm | 450 | 450 |

| Number Stations | 2 | 4 |

Deep Hole Drilling Machine is a high-precision machine tool for processing deep holes. It is widely used in aerospace, automobile manufacturing, mold manufacturing and other fields. In order to ensure its long-term stable operation and efficient processing, regular maintenance is very important. The following are some common maintenance methods:

Cleaning:

External cleaning: After work every day, wipe the outside of the machine tool with a clean cloth to remove oil and chips.

Internal cleaning: Regularly clean the chips and oil inside the machine tool, especially the guide rails, lead screws and worktables.

Lubrication:

Guide rails and lead screws: Lubricate the guide rails and lead screws regularly according to the manufacturer's recommendations, using appropriate lubricating oil or grease.

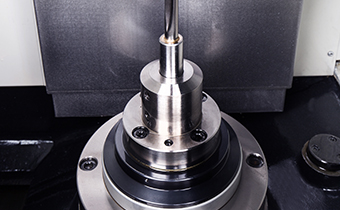

Spindle: Check the lubrication of the spindle to ensure that the lubrication system is working properly.

Inspection:

Fasteners: Check whether all fasteners are loose. If they are loose, tighten them in time.

Coolant: Check the level and cleanliness of the coolant and replace the coolant if necessary.

Application Artifact