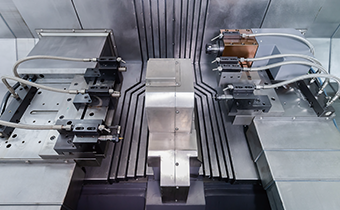

Both ends of the one clamping are processed at the same time or independently, the slanting standard cutter or turret double head CNC lathe with 100-750 mm turning length is suitable for turning, drilling, tapping and boring of precision shaft parts. Compared with traditional CNC lathe, one is equivalent to the machining efficiency of two machines, and the coaxiality can reach μ level. High precision, high efficiency, it can carry with truss or joint robot and automatical line.

Advantage

Espond to different parts

Only replace the collet and fixtures.

two ends of a clamping process at the same time

2 times efficiency, μ degree of coaxiality. Left and right independent cutter or turret optional.

Special central spindle

Response to the need for high speed and cutting rigidity.

Left and right independent cutter

Turret and milling power head can be added.

Technical Parameters

| ITEM | DNL081G | DNL082G | DNL083G |

| Max Body Rotate Diameter, mm | Ø300 | Ø300 | Ø300 |

| Clamping Diameter Scope, mm | Ø20-Ø70 | Ø20-Ø70 | Ø20-Ø70 |

| Turning Length Scope, mm | 100-300 | 300-500 | 500-750 |

| Spindle Clamp Diameter, mm | Ø70 | Ø70 | Ø70 |

| X/Z Travel, mm | 280/200 | 280/200 | 280/350 |

| X/Z Fast Speed, m/min | 18/24 | 18/24 | 18/24 |

| Fool Type | Cutter | Cutter | Cutter |

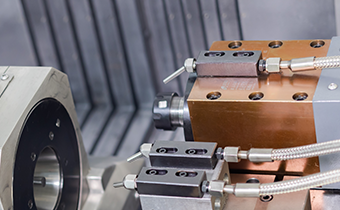

Processing both ends of the workpiece at the same time

A major advantage of the dual-spindle CNC lathe is the ability to process both ends of the workpiece at the same time. In one clamping process, the two spindles can work independently or synchronously, greatly improving production efficiency and processing accuracy. For example, when manufacturing long shaft parts, this ability not only shortens the processing time, but also reduces the errors caused by repeated clamping, ensuring the high quality and consistency of the product.

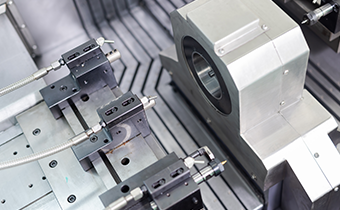

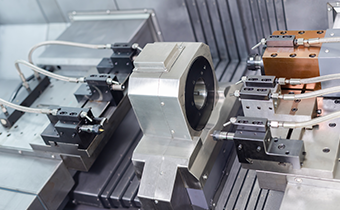

Special center spindle design

The design of the special center spindle is another highlight of the dual-spindle CNC lathe. This design allows the machine to provide higher stability and rigidity during the processing, which is particularly suitable for tasks that require high-precision processing. Compared with traditional single-spindle machines, the center spindle enhances the processing capabilities of complex shapes and fine structures, so that even extremely demanding parts can achieve ideal processing results.

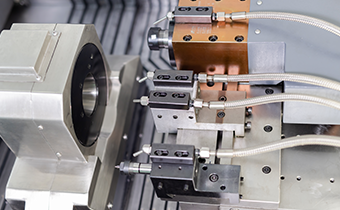

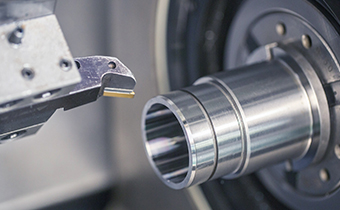

Left and right independent tool system

The configuration of the left and right independent tool system provides great flexibility for the dual-spindle CNC lathe. Each spindle is equipped with an independent turret, and the tool can be freely selected and adjusted according to the processing requirements, thereby achieving efficient and diverse processing operations. Compared with some competitors that only offer limited tool positions or require manual tool changes, this setup significantly reduces downtime and improves the overall efficiency of the production line.

Adapt to the needs of different parts

Dual-spindle CNC lathes can quickly respond and adapt to the processing needs of different types of parts. Whether it is small-batch customization or large-scale production, the machine tool can easily switch processing modes through simple programming adjustments. This is in stark contrast to some more fixed processing equipment on the market, which often takes a long time to adjust to new processing tasks, reducing production flexibility and efficiency.

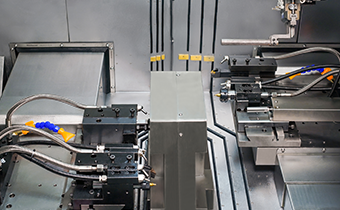

Improve the level of automation

Modern dual-spindle CNC lathes are often equipped with highly automated options such as automatic loading and unloading devices and robot integration capabilities. These features further improve the automation level of the machine tool, reduce manual intervention, and increase the time of continuous operation. In contrast, some old or basic models of machine tools may lack such advanced automation functions, limiting their application potential in high-efficiency production lines.

In summary, dual-spindle CNC lathes occupy an important position in modern manufacturing with their unique advantages, especially for those industries that pursue efficient, precise and flexible production. By combining advanced technology and innovative design, they not only surpass traditional processing methods, but also bring significant competitive advantages to users.Welcome your consultation!

Application Artifact