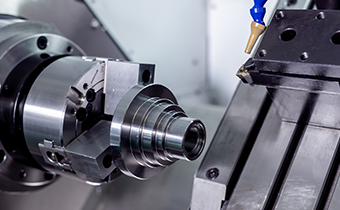

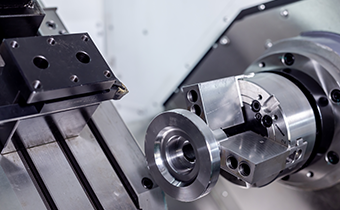

The double spindle lathe with our many years design experience, is more suitable for production line. It can carry with truss or joint robot and automatical line.

Technical Parameters

A Double Spindle Lathe is an advanced CNC lathe equipped with two spindles, typically referred to as the main spindle and the sub-spindle. This configuration allows for simultaneous machining on both spindles or sequential operations without needing to transfer the workpiece between machines.

Increased Productivity: By allowing two different machining operations to occur simultaneously or sequentially, double spindle lathes can significantly reduce cycle times and increase overall productivity.

Complex Machining: These lathes can handle more complex parts that require machining on both ends, as the sub-spindle can take over the workpiece from the main spindle for further operations.

Versatility: Double spindle lathes are versatile and can perform a variety of operations, including turning, milling, drilling, and threading, all in one machine setup.

Reduced Handling: The dual spindle design minimizes the need for manual handling of workpieces, reducing the risk of errors and improving the consistency of finished parts.

High Precision: The synchronized operation of the main and sub-spindles ensures high precision, even for complex geometries and tight tolerances.

Space Efficiency: By combining two spindles in a single machine, manufacturers can save floor space and reduce the need for multiple machines.

The double spindle lathe is a powerful tool for manufacturers seeking to optimize their production processes, reduce cycle times, and maintain high precision and quality in complex part production. Welcome your consultation!

| ITEM | NL251D |

| Max Body Rotate Diameter, mm | Ø300 |

| Max Turning Diameter, mm | Ø150 |

| Max Turning Length, mm | 200 |

| Max Bar Diameter, mm | Ø42 |

| X/Z Aris, mm | 400/250 |

| Fool Type | Cutter |

Application Artifact