Oct. 01, 2023

In today's competitive industrial landscape, efficiency and precision are paramount. Manufacturers rely on cutting-edge machinery to produce high-quality components for various industries. One such machine that plays a crucial role in this process is the Double-Head Lathe. This advanced piece of equipment offers exceptional capabilities but also demands careful attention during operation to ensure optimal performance. In this article, we will explore the various aspects of operating a Double-Head Lathe, highlighting key issues that should be given utmost consideration.

To unleash the full potential of a Double-Head Lathe, the initial setup and calibration are of utmost importance. When you acquire this sophisticated equipment, it's essential to have a trained professional or technician install and configure it correctly. Proper alignment and calibration ensure that the lathe functions at its peak performance and produces precise components.

The choice of materials is a critical aspect of operating a Double-Head Lathe. The operator must carefully select the appropriate materials based on the project's requirements. It's essential to consider factors such as hardness, density, and heat resistance to prevent damage to the machine and to produce high-quality components.

Additionally, material preparation is vital. This involves ensuring that the materials are clean, free from contaminants, and properly secured on the lathe. Any impurities or misalignment can lead to suboptimal results and potential damage to the machine.

Selecting the right tools is crucial when operating a Double-Head Lathe. Different projects may require different cutting tools and inserts. It's essential to have a comprehensive understanding of the materials being used and the specific requirements of the project to choose the most suitable tools. Dull or inappropriate tools can result in imprecise cuts and negatively impact the final product's quality.

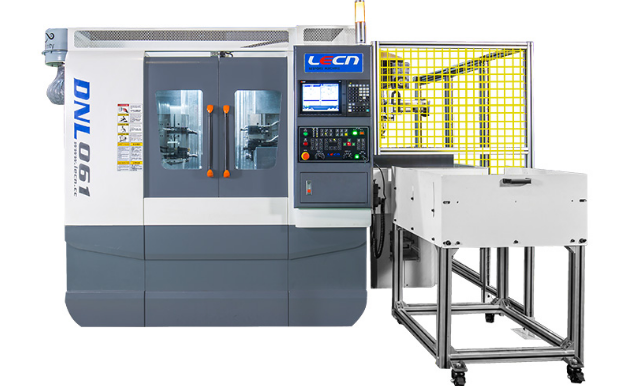

Double Head CNC Lathe DNL061/DNL062

Operating a Double-Head Lathe involves various safety considerations. Safety should always be a top priority to prevent accidents and injuries. Some key safety precautions to follow include:

Operators should wear safety goggles, gloves, and other protective gear to shield themselves from potential hazards.

Ensure the machine is enclosed with safety guards to prevent accidental contact with moving parts.

Operators must receive proper training in the safe operation of the Double-Head Lathe.

Scheduled maintenance checks are essential to ensure the machine's safety features are in working order.

Maintaining high precision and quality is the primary goal of operating a Double-Head Lathe. Quality control processes should be in place to monitor the machining process and detect any deviations. This may involve using measuring instruments such as calipers and micrometers to check the accuracy of the components being produced.

Optimizing the speed and feed rate is crucial for achieving efficient and accurate machining. Operators should have a deep understanding of how these settings affect the cutting process. Adjustments to speed and feed rates may be necessary depending on the material and tooling being used. The goal is to strike a balance between cutting speed and surface finish.

Managing the chips generated during the machining process is an often-overlooked aspect of operating a Double-Head Lathe. Proper chip management includes the use of chip conveyors or chip augers to efficiently remove the chips from the work area. Accumulated chips can interfere with the machining process and lead to damage to the machine or workpiece.

Operating a Double-Head Lathe can generate heat, noise, and coolant waste. Environmental considerations are essential in maintaining a sustainable and safe work environment. Proper ventilation, noise reduction measures, and responsible coolant disposal are vital to ensure a comfortable and eco-friendly workplace.

Operating a Double-Head Lathe is a sophisticated endeavor that demands meticulous attention to detail. From the initial setup to tool selection, safety precautions, precision control, and environmental responsibility, every aspect plays a crucial role in achieving exceptional results. By following these guidelines, you can ensure that your Double-Head Lathe operates at its best, producing high-quality components for various industries.

Previous: None

Next: None