Jun. 08, 2022

CNC machining costing seems to be quite complex. There are many factors to consider, and the final cost assessment is more difficult than with other manufacturing methods.

For example, our own platform can calculate laser cutting prices in a matter of seconds. This method takes into account material usage, cutting time and geometry. It is much more difficult to do the same thing for CNC milling and turning services.

We'll explain why below, taking a closer look at the factors that make up the cost of CNC machining.

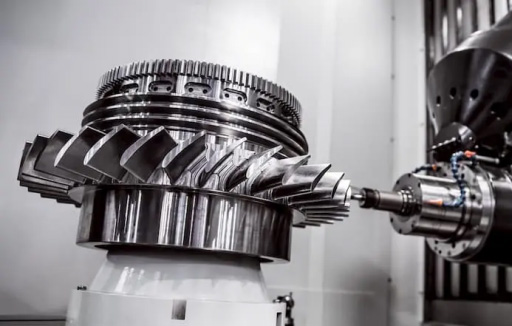

CNC machining is a subtractive method of producing parts. This means that these operations remove material. It can be used to create the necessary parts from a variety of materials, including metals, plastics, etc.

The first sentence pretty much covers the essence of CNC machining, distinguishing CNC turning and milling from other manufacturing methods that use computer numerical control. Both turning and milling start with a larger block of material, which is then carved to achieve the desired result.

CNC machining prices include several different aspects. Namely, labor and machine costs, tooling, tool wear, materials and setup.

Taking all of these into account can be difficult, as it is difficult to make an accurate assessment of each category. At the same time, there is no way to turn a blind eye to any one of these components of the final price.

Almost all of these parameters are directly related to time, with materials being the only exception. Before we can put a price tag on any of them, we need to evaluate the time consumption. And this is the most difficult part of the whole process.

Almost all appropriate shops have some sort of computer-aided manufacturing program. The most basic is CAD-CAM software, which has both design and CAM capabilities.

CAM programs require input in the form of 3D models. Based on these, they use a library of tools and information provided by the shop owner about the details of his machine to generate the entire manufacturing process.

The CAM software creates the G-codes that are responsible for guiding the cutting head, rotation speed, etc. Basically everything related to the production side of the process. m-codes determine tool changes, coolant usage, etc. All of these come with time estimates for each operation.

So we can see how long the whole process took, how much work was done by individual tools, how many tool changes occurred, etc. The machine operator can also adjust the program to better suit his machine or when he sees a better way to produce the part.

But here's the important part - the CAM software can evaluate the time it takes to make the part.

This is all based on 3D models. If you don't have them, quoting usually relies on using Excel sheets and a combination of common sense and previous experience. While bringing intuition into the frame may seem highly inaccurate, it's not.

That's why it's possible to automate the entire pricing process through artificial intelligence. Using part parameters and comparing them to previous work, their production times and costs can lead us to a fairly optimal price point.

The customer must reimburse the store for the purchase price of the machine. The average machine shop recovers its initial investment on the basis of 5,000 hours. The market price for even used CNC machines can be quite high, although these machines may be less cost-effective due to speed limitations and less automation.

Therefore, assume that your part has a machining time of 0.5 hours. The first step towards the final price is then to add 1/10,000th of the machine price to the production cost.

The standard hourly price for 3-axis machining is about £30. Multi-axis costs are higher, up to 3 times the price. But depending on the geometry of your part, these more advanced CNC centers can save a lot of time.

The first point is of course your own time or that of the designer. Then comes the manufacturing engineer. He will review the manufacturability of your design. If the part you designed is defective, he will have to come back and suggest changes. Expertise like this comes at a price.

Next is the machine operator. He spends his time setting up the machine for custom CNC jobs and making sure everything is executed in a way that produces good results.

Each part requires a new setup, which is what makes mass production significantly less expensive per part.

CAD programs can make very accurate mass calculations for parts based on the volume of the part and the density of the material. All you need to do is select the correct material from the drop-down menu.

However, CNC machining costs include more material than the final product itself indicates. As a subtractive manufacturing method, there is a fair amount of scrap.

A CNC milling machine works from a single piece of material. Therefore, general dimensions plus a little extra are necessary to produce the final part.

When it comes to turning, the starting point is usually a round stainless steel bar. It is important to note that while your part has specific dimensions and the "extra bit" does not have to be significantly larger than the general dimensions of the final product, the material has standard dimensions.

For example, suppose you want to produce a shaft with a maximum diameter of 33 mm. The nearest standard round steel is 35 mm. Therefore, this is the raw material for the CNC machined part and additional turning operations are required to achieve the basic dimensions.

As mentioned earlier, the CAM software determines which milling tools are used to produce your part. This depends on your tool library and can be changed by the manufacturing engineer if necessary.

It is not uncommon that a specific job may only require the purchase of separate tools for this purpose, as is the case with metal bending services. While these tools will stay on the shop floor, the customer may have to pay some additional costs if this tool is specific enough to not be of much use later.

In addition, tool wear and tear is considered based on the time calculations and tool life provided in the documentation. The customer must bear these costs.

Finally, creating a part usually requires a tool change unless it is very simple. While modern CNC machining centers may have real-time machining possibilities, not every job shop has access to these. As a result, this adds another manual labor to the whole process, which is reflected in the final machining price.

As you can see, there are many factors to consider when calculating the cost of CNC machining. This is why many suppliers take their time before providing a quote.

Making a mistake here and there can result in prices that are not profitable for the manufacturer, or simply overpriced to bring in the work.

We at LECN have always wanted to provide CNC machining quotes within 48 hours while fully automating the process in the future, just as we have done with other manufacturing methods to date.

Previous: None

Next: None