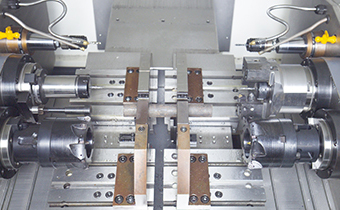

Both ends of the one clamping are processed at the same time, the oblique facing and centering machine with 300-1500 mm workpiece length is suitable for milling, chariot, drilling center hole, drilling, tapping, boring, reaming, grooving package of all kinds of slender, irregular and stepped parts. High coaxiality, high efficiency, chip easily, it can carry with truss or joint robot and automatical line.

Advantage

Hydraulic self-centering jig

Clamping reliable, accuracy stability.

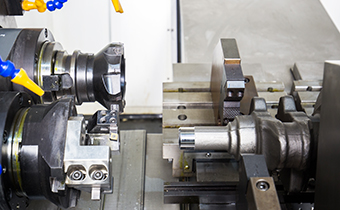

CNC spreading tool

CNC tapping

Automation

Factory high stability automation.

Technical Parameters

| ITEM | SZ8210120 | SZ8210150 |

| Clamping Diameter Scope, mm | Ø15-Ø100 | Ø15-Ø100 |

| Workpiece Length Scope, mm | 300-1200 | 300-1500 |

| Max Center Drilling Clamping Diameter, mm | Ø26 | Ø26 |

| Max Milling Amount(One Side), mm | 5 | 5 |

High-precision machining

These machines are capable of very high machining accuracy, especially when processing complex geometries. The precision control system and high-rigidity structural design ensure that each machining is extremely accurate.

Multifunctional operation

Beveling and centering machines are usually equipped with a multifunctional tool system that supports a variety of machining methods, such as beveling, end machining, drilling, etc. This allows one machine to complete multiple processes, reducing the need to transfer workpieces between different equipment.

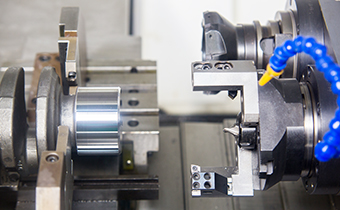

Improved production efficiency

The ability to complete multiple machining tasks in one clamping, including beveling and centering, greatly shortens the time of the entire manufacturing process. This integrated solution helps to improve the overall efficiency of the production line.

Strong adaptability

This type of equipment is suitable for machining a variety of materials, including but not limited to steel, aluminum alloys and other non-ferrous metals. Its flexibility allows users to adjust parameter settings according to different material properties and processing requirements to achieve the best results.

High degree of automation

Modern beveling and centering machines are often equipped with advanced automation features, such as automatic tool changers (ATCs), automatic loading and unloading systems, etc. These features not only improve production continuity, but also reduce labor costs and operating difficulties.

Improve product quality

The precise center positioning function ensures the alignment accuracy of the workpiece in subsequent processing, thereby reducing quality problems caused by inaccurate positioning. This is especially important for products that require strict tolerance control.

Reduce material waste

Through precise cutting path planning and optimized processing strategies, this type of machine can minimize the waste of raw materials while ensuring the quality of the finished product, thereby reducing production costs.

For more product information, please contact us!

Application Artifact