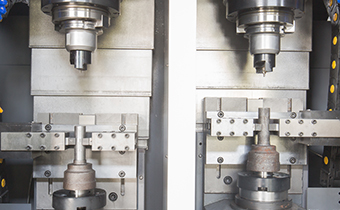

Duplex CV joint horizontal scraping and milling machine with one-time clamping and processing end face and hole, 50-300 mm processing of workpiece, which is suitable for the milling end face and drilling center hole. Duplex high efficiency, it can carry with truss or joint robot and automatical line.

Advantage

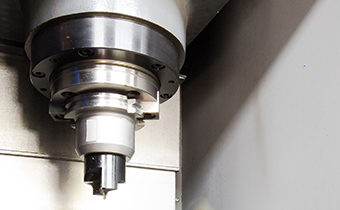

Special high rigidity spindle structure

Seismic resistance, long life.

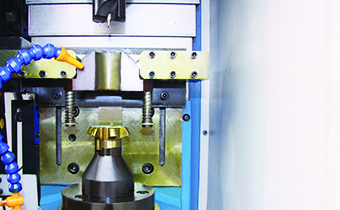

Special hydraulic clamp

Clamping reliable, accuracy stability.

Clamp can be choosed

Respond to different workpiece fix position.

Operate independent

Set parameters independent,and can operate independent,high efficiency.

Technical Parameters

The special high-rigidity spindle structure enhances stability during processing. This minimizes vibration and deflection, ensuring consistent cutting performance and precise machining results.

The high-rigidity spindle structure reduces spindle deflection, thereby improving machining accuracy and dimensional consistency of machined parts. This ensures tight tolerances and a high-quality surface finish that meets the stringent requirements of constant velocity joint manufacturing.

Improved stability and precision of the spindle structure enable higher cutting speeds and feed rates, resulting in increased productivity and shorter machining cycle times. This allows manufacturers to meet production needs more efficiently and reduce overall manufacturing costs.

Highly rigid spindle construction reduces vibration and spindle deflection, helping to extend tool life. This minimizes tool wear and breakage, thereby reducing tool costs and downtime associated with tool changes and replacements.

| ITEM | VQG0430D |

| Max Clamping Diameter, mm | Ø40 |

| Max Workpiece Length, mm | 50-300 |

| Max Center Drilling Clamping Diameter, mm | Ø16 |