Shock absorber | Turning

Shock absorber is a car in the process of use vulnerable parts, shock absorber work, will directly affect the car running stability and other parts of the life, so that the shock absorber often in a good working state.

Crafting process

Workpiece case

| Workpiece name | Shock absorber |

| Machine type | DNL083 |

| Manufacturing procedure | Both ends of cylinder turned simultaneously |

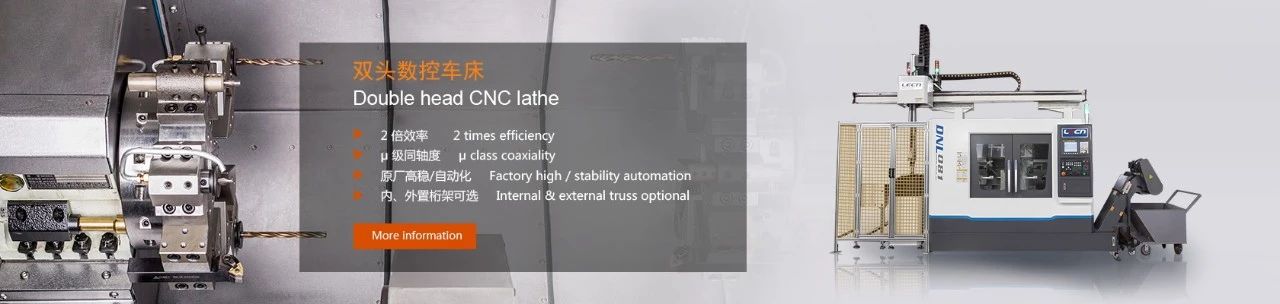

Double head CNC lathe is mainly designed for the double-sided simultaneous turning of the mandrel in automobile and motorcycle shock absorbers, automobile transmission shaft, motor shaft and other small shaft parts, and undertakes both ends of the eccentric shaft simultaneously processing and drilling and milling composite processing.

The scope of application of double head CNC lathe: it has the functions of turning cylindrical surface, conical surface, circular arc surface, end surface, groove cutting, drilling and reaming hole and various threads.The system can be independently selected to meet your different processing needs.Used in automobile and motorcycle parts, valves, power tools, hardware instruments and other industries, can be a variety of metal and non-metal processing.

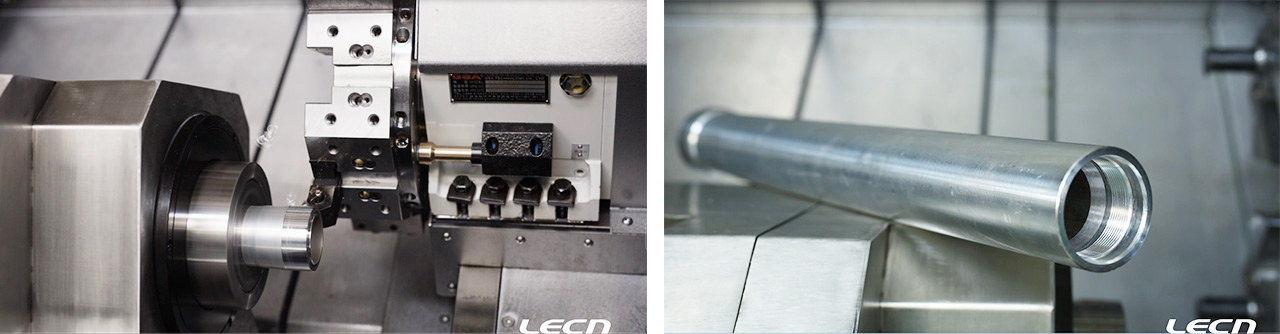

▲ inclined integral frame body,rigidity,easy chip;

The inclined one-piece frame structure design makes the machine have higher rigidity and stability during processing. This design can not only effectively reduce vibration and deformation during processing, but also improve processing accuracy and surface quality. In addition, the inclined structure helps the natural discharge of chips and avoids chip accumulation, thereby reducing the interference of chips on the processing area and improving processing efficiency and safety.

▲ respond to fifferent parts,only replace the collet and fixtures;

The chuck and fixture of the machine adopt a modular design and can be quickly replaced to meet the processing needs of different parts. This design not only improves the flexibility of the machine, but also reduces the line change time and improves production efficiency. Through simple tool replacement, the machine can quickly switch between different processing tasks, which is suitable for multi-variety small batch production environments.

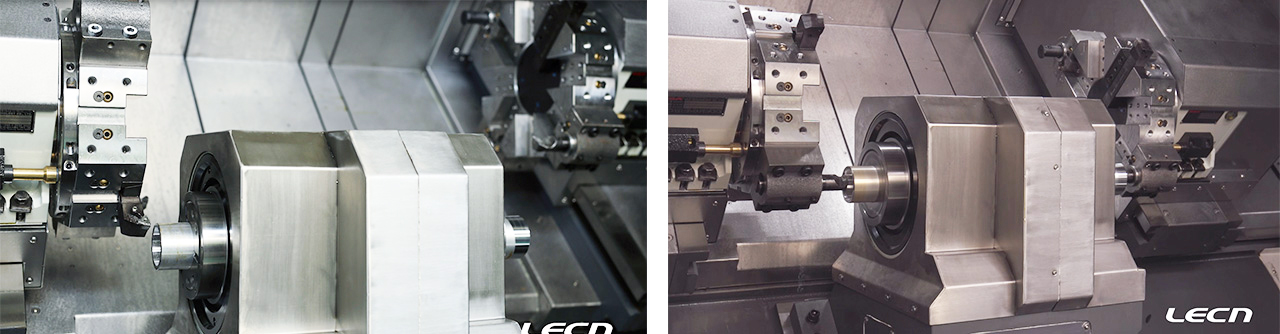

▲ fix one time,processing both end at one time,high efficiency,good precision;

The machine design allows the processing of both ends of the part to be completed in one clamping, which not only reduces the cumulative error caused by multiple clamping, improves processing accuracy, but also significantly improves production efficiency. The synchronous processing capability enables the machine to process both ends of the part at the same time in one clamping process, ensuring the consistency of size and position, which is particularly suitable for the processing of long shaft parts.

▲ the special structure central spindle can respond to high speed and cutting rigid;

The central spindle adopts a special structural design that can support high-speed rotation and high-rigidity cutting. This design not only meets the needs of high-speed processing, but also can remain stable during high-speed cutting, reduce vibration and thermal deformation, and ensure processing accuracy. The high-rigidity spindle design also extends the service life of the spindle and reduces maintenance costs.

▲ independent turret;

The machine is equipped with independently controlled turrets, each of which can be controlled separately to achieve multi-task parallel processing. This design improves processing efficiency and enables the machine to complete multiple processes in one clamping process. The turret can also be equipped with different types of tools according to processing requirements, increasing the flexibility of the machine. The fast tool change mechanism further shortens the tool change time and improves production efficiency.

▲ dual-channel controller,easily respond to synchronization processing;

The dual-channel controller can control two independent processing units at the same time to achieve synchronous processing. This design ensures high-precision synchronization between the two processing units and avoids quality problems caused by synchronization errors. The user-friendly controller interface makes programming and debugging easier, improving the convenience and reliability of operation.

▲ can carry with truss or joint robot and automatical line.

The machine can be integrated with automation equipment such as trusses and articulated robots to achieve a fully automated processing flow from loading to unloading. This integration not only improves production efficiency, but also reduces manual intervention, and improves the safety and consistency of production. It is suitable for large-scale production and tasks that require high-precision and high-efficiency processing, and can achieve 24-hour uninterrupted production.

| ITEM | DNL083 |

| max body rotate diameter, mm | Ø300 |

| clamping diameter scope, mm | Ø20-Ø70 |

| turning length scope, mm | 500-750 |