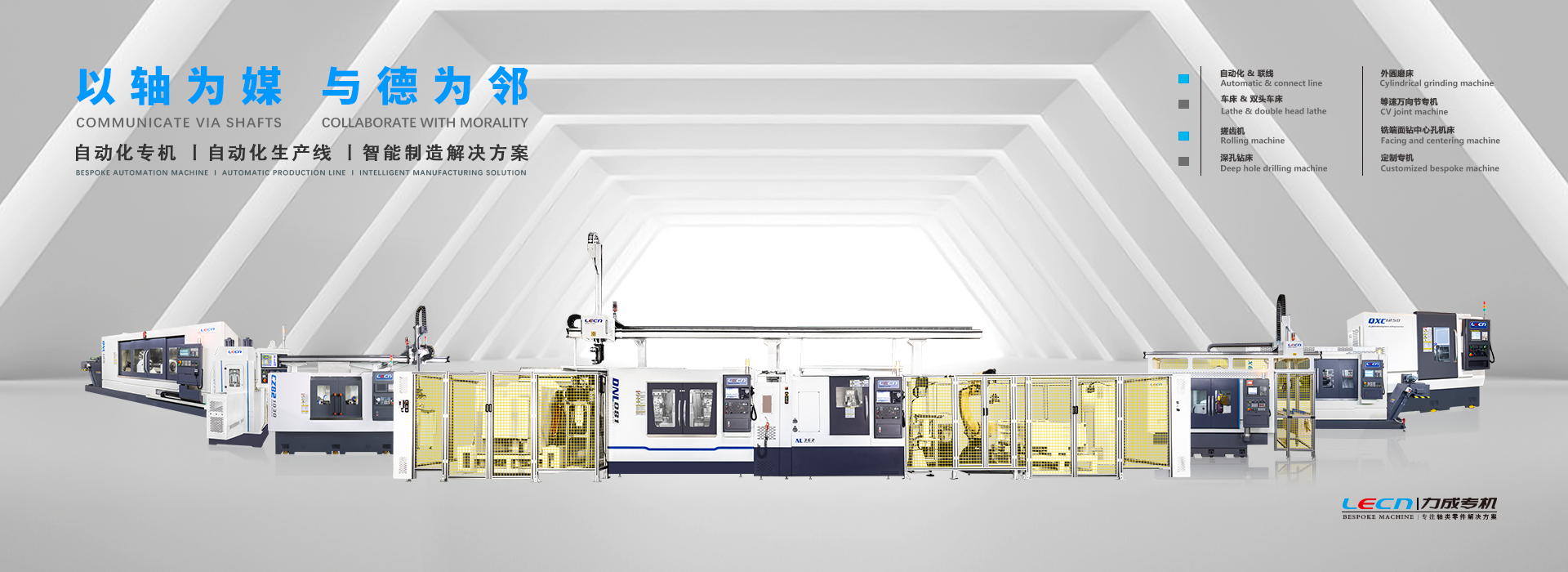

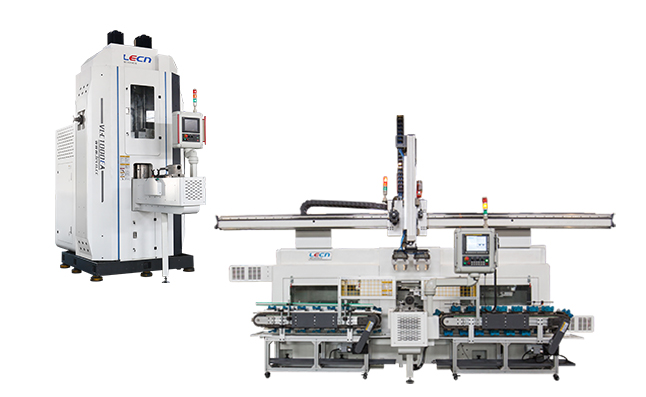

Automatic & Connect Line

Automatic & Connect Line

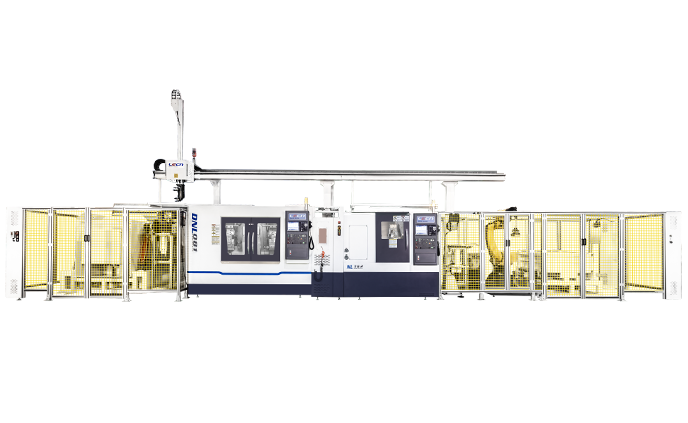

Lathe & Double Head Lathe

Lathe & Double Head Lathe

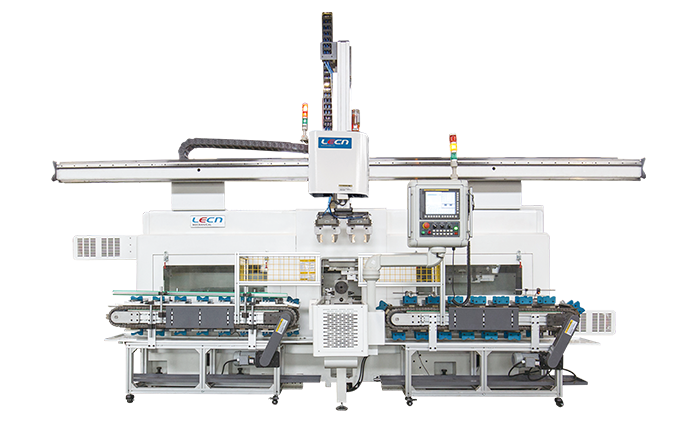

Rolling Machine

Rolling Machine

Deep Hole Drilling Machine

Deep Hole Drilling Machine

Cylindrical Grinding Machine

Cylindrical Grinding Machine

CV Joint Machine

CV Joint Machine

Facing And Centering Machine

Facing And Centering Machine

Customized Bespoke Machine

Customized Bespoke Machine

The plate rolling machine is forging equipment used to bend metal plates. It is dedicated to the forming and bending work of metal plates. This plate rolling machine can pre-bend and roll various cylindrical and arc-shaped parts with the help of auxiliary equipment. Rolling of cone-shaped cylinders can be carried out. It is one of the key metal fabrication equipment in the boiler, shipbuilding, petrochemical, metal structure, cement machinery, chemical machinery, machinery manufacturing, and maintenance departments.

LECN, as a professional rolling machine manufacturer, can provide you with vertical plate rolling machines as well as horizontal plate rolling machines, if there are other customised requirements, you can also contact us, we will provide you with the most professional solutions.

Plate rolling machines typically have three rollers arranged in a triangular configuration: two side rollers and one top roller. The position and movement of these rollers allow for the bending of the metal plate.

The metal plate is inserted between the top and side rollers. The top roller can be adjusted to apply downward force, causing the plate to bend around the side rollers.

The plate is gradually fed through the machine, and as it passes through, it takes on the desired curvature.

Our advanced plate rolling machines feature CNC (Computer Numerical Control) capabilities, allowing for automated and precise control over the bending process. CNC controls can store and repeat bending programs, making the process more efficient and accurate.

Plate rolling machines are often capable of pre-bending, which involves bending the leading and trailing edges of the plate before the main bending operation. This helps achieve a more uniform curvature along the entire length of the plate.

Safety features are important, and our plate rolling machines are equipped with safety devices such as emergency stop buttons, safety interlocks, and guards to protect operators.

Read More

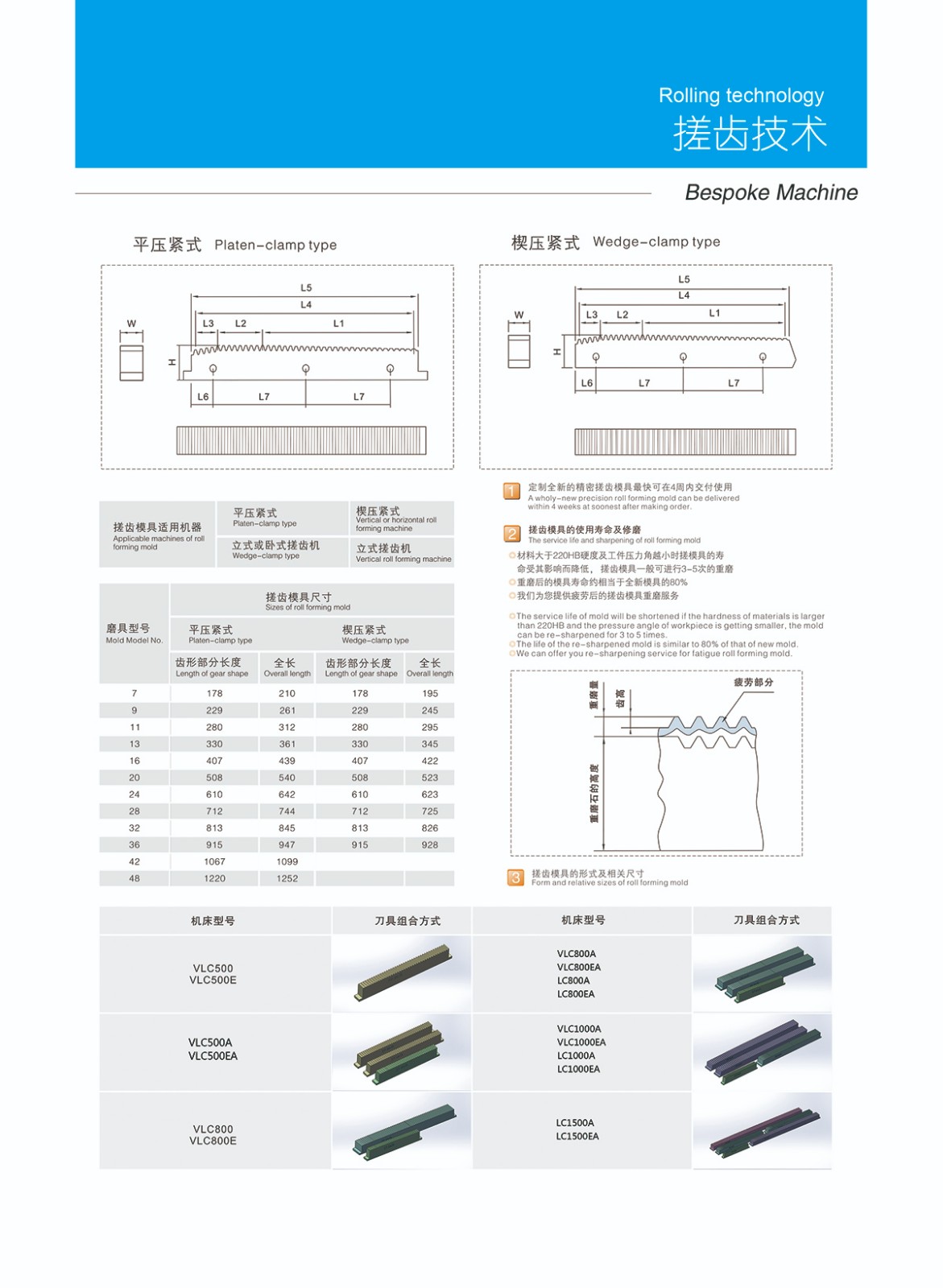

Vertical Rolling Machine

Vertical Rolling Machine VLC500E

Max Module: 1.0 mm

Max Out Diameter: Ø20 mm

Max Tool Width: 40 mm

Max Installing Tool Width: 90 mm

Vertical Rolling Machine VLC500EA

Max Module: 1.0 mm

Max Out Diameter: Ø20 mm

Max Tool Width: 40 mm

Max Installing Tool Width: 300 mm

Vertical Rolling Machine VLC800E

Max Module: 1.3 mm

Max Out Diameter: Ø40 mm

Max Tool Width: 80 mm

Max Installing Tool Width: 120 mm

Vertical Rolling Machine VLC800EA

Max Module: 1.3 mm

Max Out Diameter: Ø40 mm

Max Tool Width: 80 mm

Max Installing Tool Width: 300 mm

Vertical Rolling Machine VLC1000EA

Max Module: 1.5 mm

Max Out Diameter: Ø50 mm

Max Tool Width: 100 mm

Max Installing Tool Width: 300 mm

Horizontal Rolling Machine

Horizontal Rolling Machine LC730

Max Module: 1.3 mm

Max Out Diameter: Ø40 mm

Max Tool Width: 60 mm

Max Installing Tool Width: 90 mm

Horizontal Rolling Machine LC800A/LC800EA

Max Module: 1.3 mm

Max Out Diameter: Ø40 mm

Max Tool Width: 80 mm

Max Installing Tool Width: 300 mm

Horizontal Rolling Machine LC1000A/LC1000EA

Max Module: 1.5 mm

Max Out Diameter: Ø50 mm

Max Tool Width: 100 mm

Max Installing Tool Width: 300 mm

Horizontal Rolling Machine LC1500A/LC1500EA

Max Module: 1.75 mm

Max Out Diameter: Ø60 mm

Max Tool Width: 120 mm

Max Installing Tool Width: 300 mm

Horizontal Rolling Machine LC2000EA

Max Module: 2.0 mm

Max Out Diameter: Ø70 mm

Max Tool Width: 150 mm

Max Installing Tool Width: 300 mm

Technology and Application

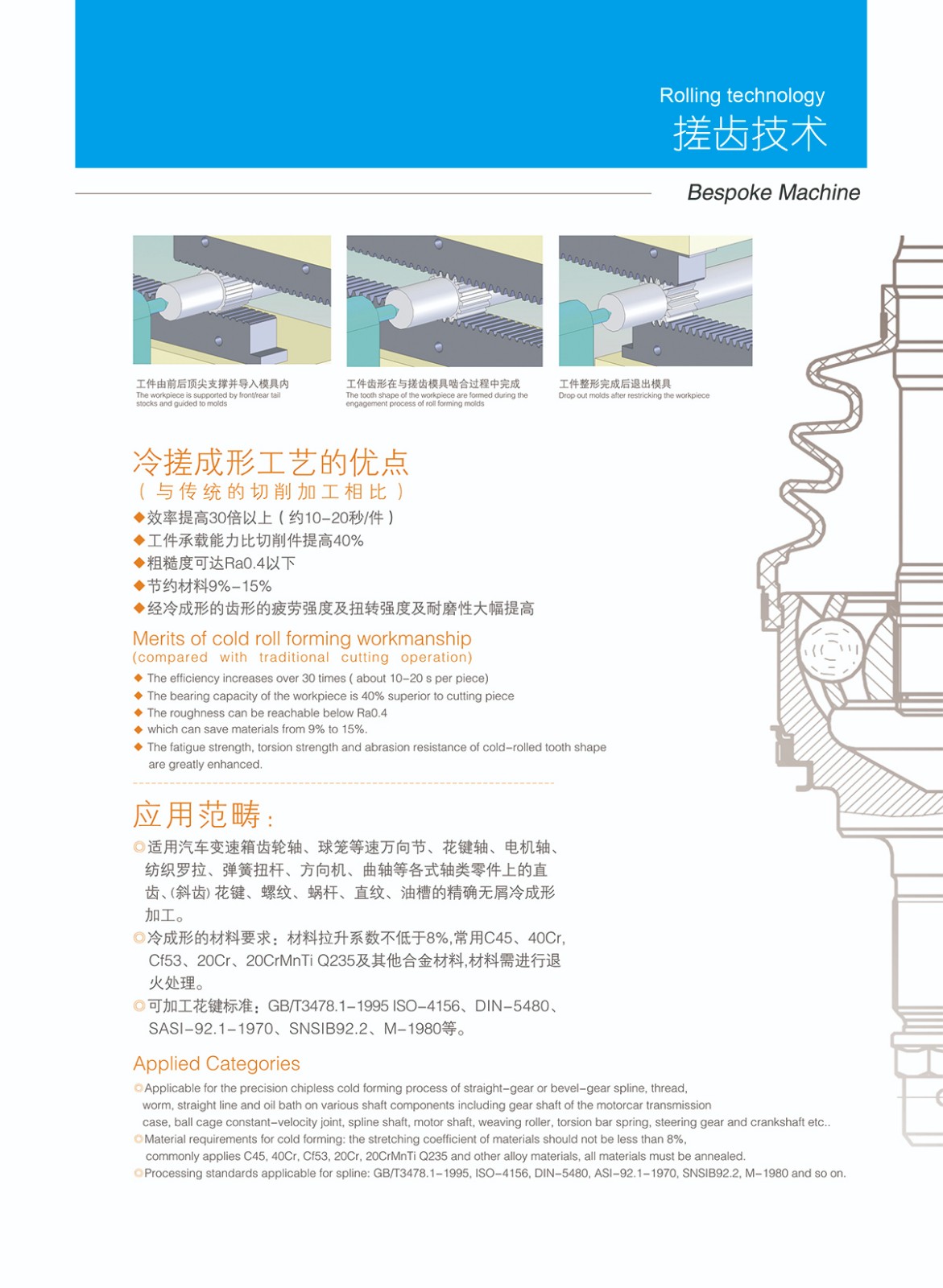

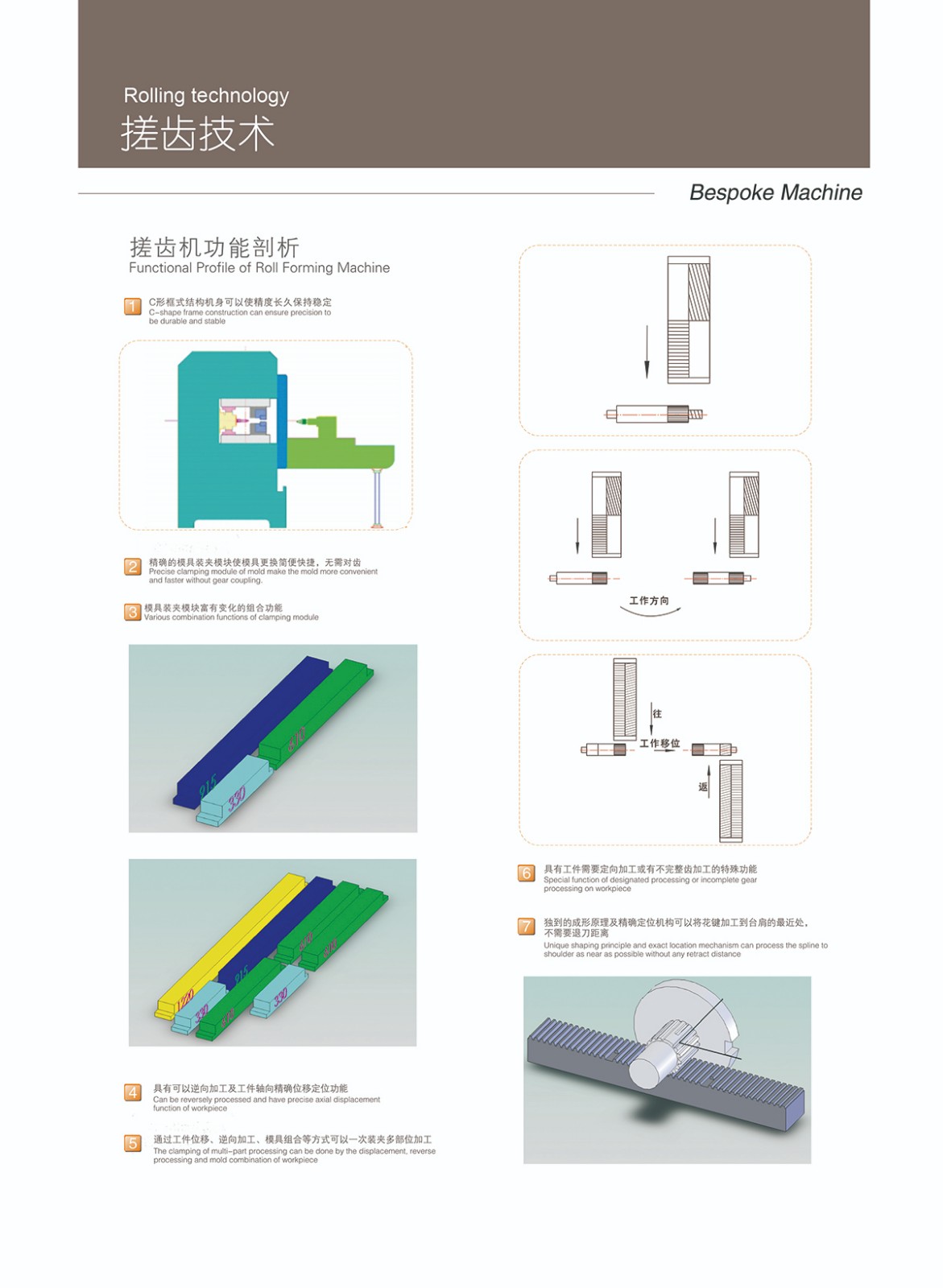

Processing advantages and applications of rolling machine

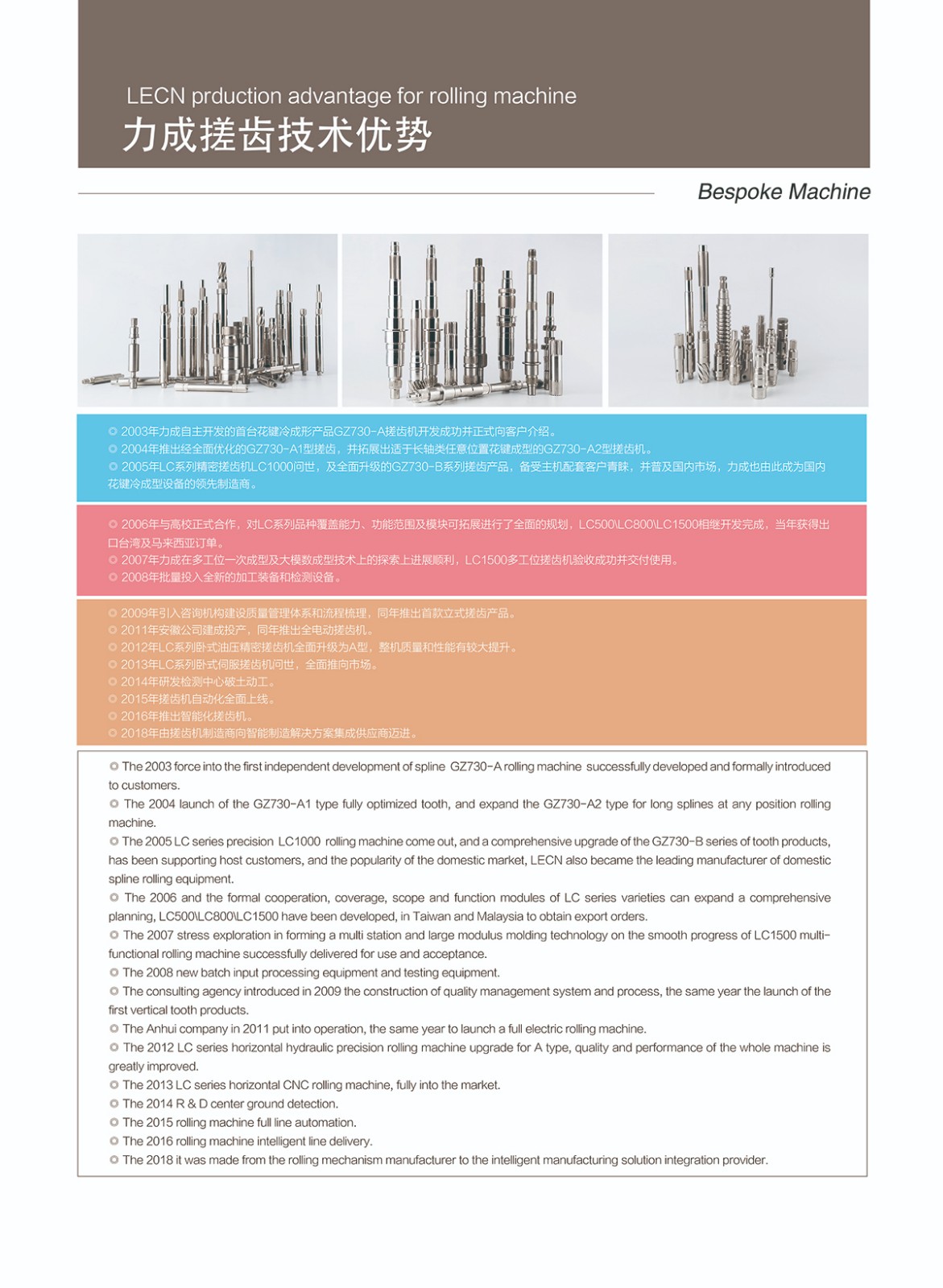

LECN supply the most professional service and the most comprehensive products for customers, rolling technology is LECN the most important research and development field, in past ten years we has supply more than 1000 sets rolling machine for more than 300 customers, ranged cover such as motor gearbox, engine, transmission shaft, traversing torsion bar, start motor, brake, spring torsion bar, textile roller, laundry machine parts, motor, elevator, reducer and so on.

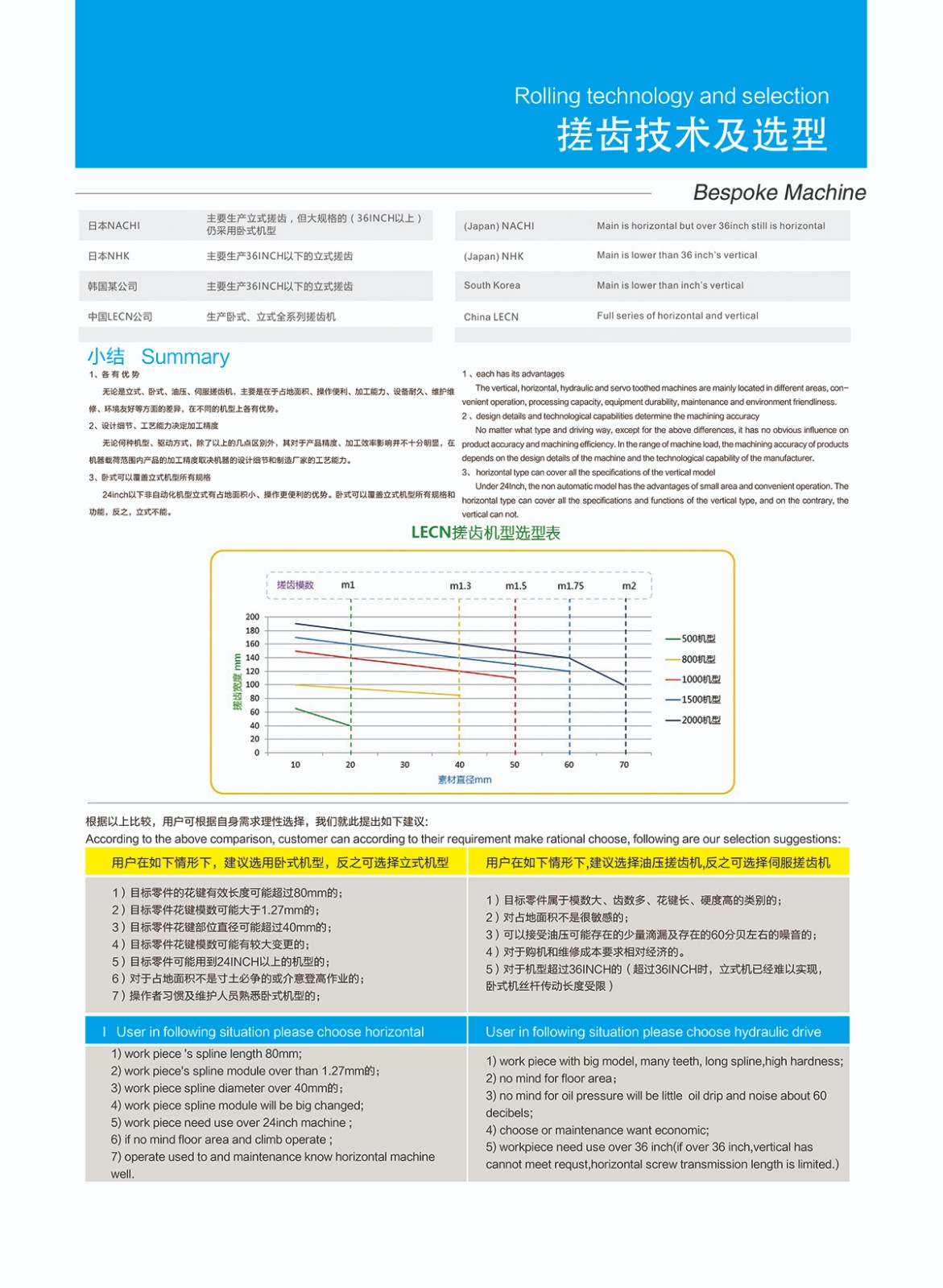

Quickly understand how to choose rolling machine

LECN covered all series of vertical, horizontal, hydraulic drive, CNC, full series rolling machines and experience in manufacturing and services. In order to customer choose the correct one from different quality similar machine, we list different rolling machine information hope can have any help for you.