Technical Parameters

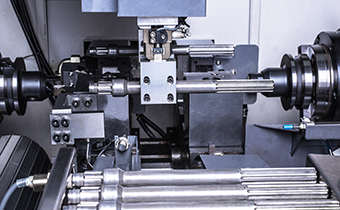

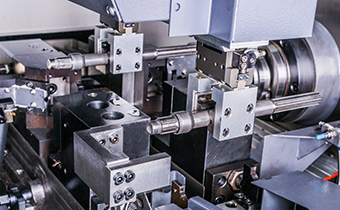

CNC Facing And Centering Machine are primarily used to ensure the proper alignment and positioning of workpieces before machining. These machines perform two fundamental operations:

Facing: The facing operation involves removing material from the surface of a workpiece to create a smooth, flat surface that is perpendicular to the rotational axis of the machine. This process helps achieve parallelism, flatness, and desired surface finishes.

Centering: Centering refers to aligning the rotational axis of the workpiece with the spindle axis of the machine. This ensures accurate and concentric machining operations, reducing errors and improving the overall precision of the finished product.

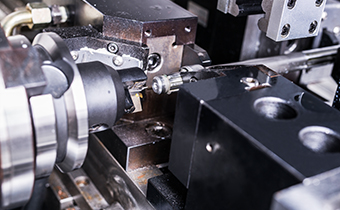

Precision Machining: Ideal for producing high-precision parts required in aerospace, automotive, and electronics industries.

Prototyping and Toolmaking: Perfect for creating and refining new designs, molds, dies, and tooling before full-scale production.

Small to Medium Batch Production: Efficiently handles custom or specialty parts production with quick setup times.

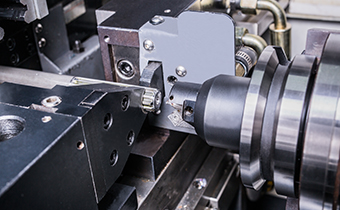

A Facing and Centering Machine is a versatile and efficient solution for precision machining in various industries. Its ability to perform multiple operations in a single setup, coupled with automation integration, makes it an invaluable asset in modern manufacturing. Welcome your consultation!

Application Artifact