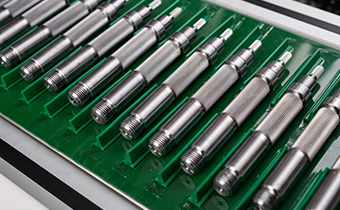

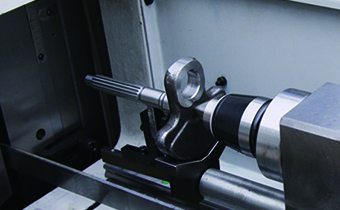

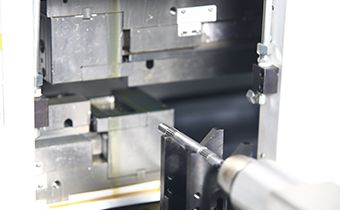

Single or reverse rolling,13 to 16 inch vertical mini CNC rolling machine,it is suitable for the cold rolling of involute(straight tooth,helical tooth,bevel tooth,missing tooth ,merge,tooth)spline,worm,thread,anilox roller,straight grain,oil groove and other precision non chip parts on the small modulus and digital shaft.Compact,precise,efficient and environmental friendly,it can carry with truss or joint robot and automatical line.

Advantage

Rich mold combination

Can save reverse roll forming mold.

Double servo motor full closed-loop drive

Llow noise and precise forming process.

Intelligent all-around top servo technology

Effectively solve clamping secure identification.

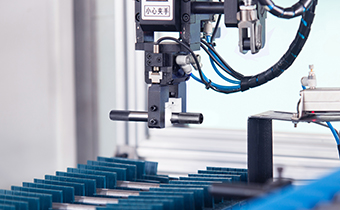

Automation

Factory high stability automation.

Technical Parameters

| ITEM | VLC500E |

| Max Module, mm | 1.0 |

| Max Out Diameter, mm | Ø20 |

| Max Tool Width, mm | 40 |

| Max Workpiece Length, mm | 400 |

| Max Installing Tool Width, mm | 90 |

| The Open Part Size, mm | 139.7 |

| Tool Size, inch | 13&16 |

| Max Travel, mm | 500 |

| Drive Way | CNC |

| Special Specifications Can Be Customized | |

Precision Control: AVRMs incorporate advanced control systems that allow operators to set specific parameters for rolling operations, ensuring high accuracy and repeatability. This is crucial for maintaining tight tolerances and achieving consistent product quality.

Automation: The level of automation can vary from semi-automatic to fully automatic systems. Fully automated machines can operate with minimal human intervention, significantly increasing productivity and reducing labor costs. They can also integrate with other manufacturing systems for seamless workflow management.

Versatility: AVRMs can handle a wide range of materials, including steel, aluminum, and other alloys, making them suitable for various applications. Additionally, they can process different thicknesses and sizes of sheets or plates, adding to their flexibility.

Safety Features: Modern AVRMs come equipped with safety features such as emergency stop buttons, safety barriers, and sensors that monitor the machine's operation to prevent accidents and protect workers.

User-Friendly Interfaces: Many AVRMs feature intuitive user interfaces that simplify setup and operation. Touchscreen displays and graphical user interfaces (GUIs) provide real-time feedback and easy access to machine settings.

Maintenance and Durability: Built to withstand heavy-duty use, these machines often have robust designs with wear-resistant components. Regular maintenance is essential to ensure long-term reliability and optimal performance.

Energy Efficiency: Advanced AVRMs are designed to be energy-efficient, which not only reduces operating costs but also minimizes environmental impact.

Application Artifact